Machines

DGH-PRO-600

DGH-PRO-600

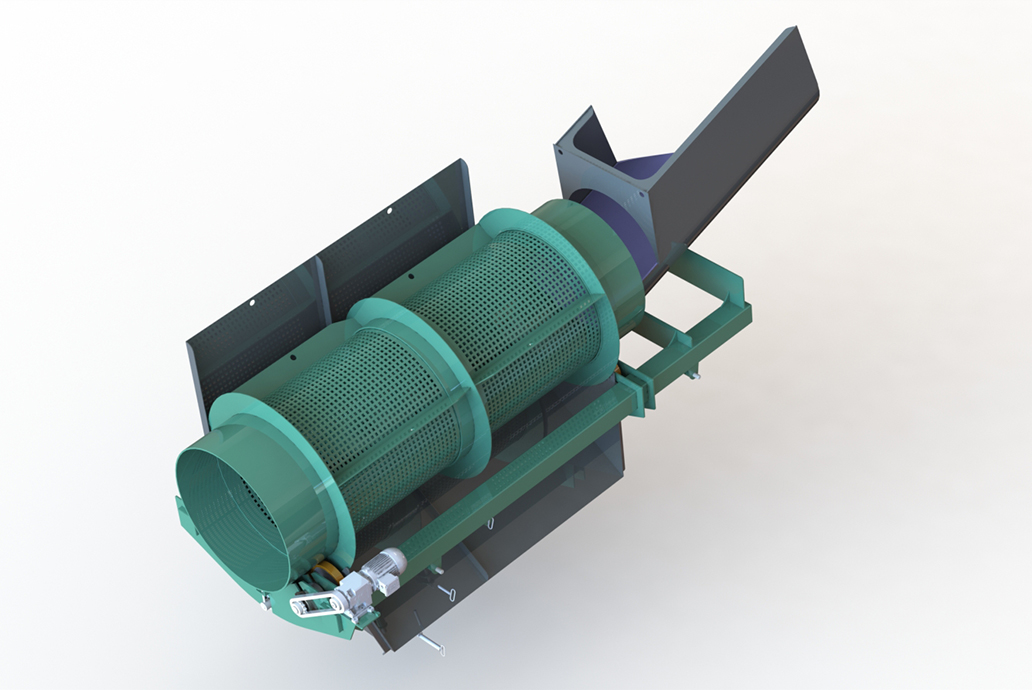

The DGH-PRO-600 is a combination of our DG-PRO-400 machine paired with a horizontal splitter similar to the splitter on the DH-PRO-600 machine. It is ultimately able to process logs with diameters from 8 to 60 cm. The wood is placed on a feed belt and is moved automatically towards the saw. A measuring roller descends onto the wood and, in contact with a hydraulic stop, determines the length of the wood and holds it in place before it is cut by the circular saw. For wood less than 40 cm in diameter, logs fall onto a catch pan on which a patented push-pull rod moves the wood simultaneously to two splitting heads, 2/4/6 or 2/4/8, positioned opposite each other. Thanks to this innovative mechanism, the push-pull rod never returns empty, thus optimising production cycles and guaranteeing unrivalled speed. Depending on the diameter of the log and the desired billet size, the catch pan is positioned vertically in front of the relevant splitting head. If the wood measures between 40 and 60 cm in diameter, it is automatically carried towards the horizontal splitter. A retractable drawer removes the woodscrap, whilst the billets fall into a billet scraper positioned under the machine, which moves them directly towards the container of your choice.

Multiple high-performance benefits:

Productivity: the DGH-PRO-600 is capable of processing a large volume of wood with diameters from 8 to 60 cm within record time, with just one operator.

Robustness: designed for intensive use, it withstands the most demanding operating conditions.

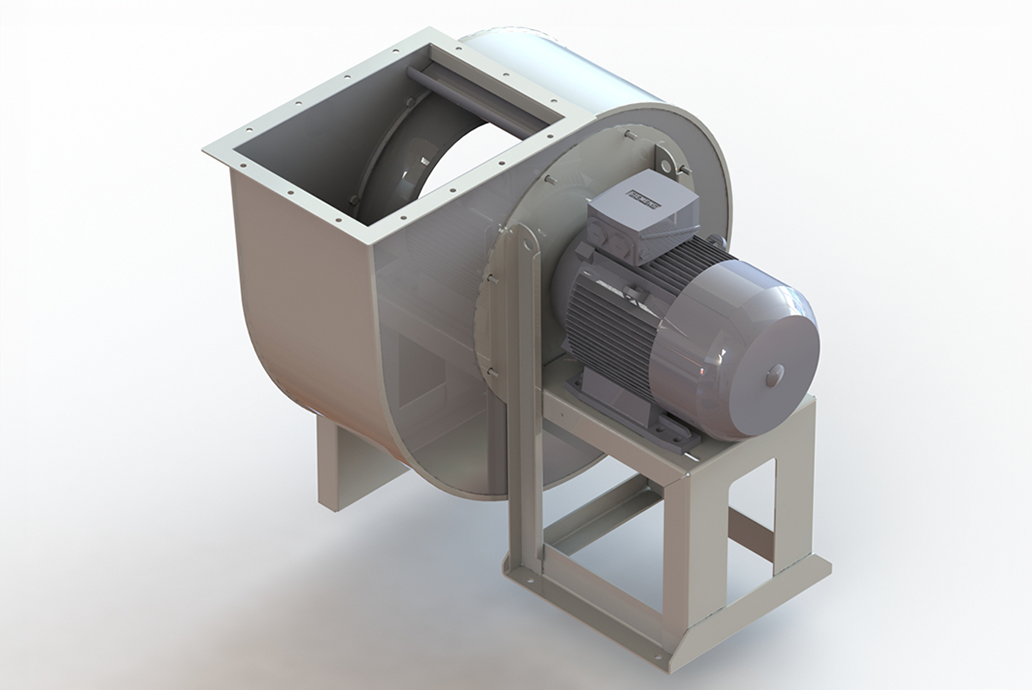

Power: our hydraulic power packs developed in-house guarantee high production rates, accompanied by motors sourced from major manufacturers.

Advanced automation: thanks to smart systems, the machine reduces end-of-stroke losses and guarantees a high-quality finished product.

Remote management: all anomalies are detected rapidly by an integrated system, thus facilitating maintenance and reactivity.

Safety: full automation of the DGH-PRO-600 ensures maximum protection for operators and accessories.

Personalisation: do you need to process longer logs, clean billets or add other outfeed conveyors? Each configuration can be modified to adapt to your specific requirements.

Technical data

Wood diameter

From 8 to 60 cm

Length of logs

From 18 to 50 cm

Cutting system

Circular

Splitting

Double splitting head 2/4/6 22T + Horizontal 2 x 22T

Commands

Automatic

Drive

Electric

Kindling production

No

Wood loading system

15 mm steel feed belt + hydraulic stop

Wood holding system in the saw

Roller

System for tilting wood towards the splitter

Drawer

Wood holding system in the splitter

Motorised catch pan + hydraulic press

Type of circular saw

Carbide blade

Splitter actuators

200 to 300 bars

Motor power

45 kW

Oil volume

800L

Electric

General PLC + safety relay or safety PLC

Oil flow rate

250,00

OPTION

Remote control

Photos

Photos