Machines

DH-PRO-600

DH-PRO-600 T/P

The vertical splitting machines category includes the DV-PRO-600, which is a compact machine designed for firewood producers who process wood with diameters of 8 to 60 cm. Two independent splitting blades in wear-resistant steel perform optimal splitting. A single blade can be commanded to split small round logs with a minimum diameter of 8 cm.

Two configurations adapted to every requirement:

Equipped with a feed belt with a double lug chain, this model conveys the log towards a saw, which can be:

- A chainsaw

OR - A circular saw with a diameter of 165 cm

As an option, a hydraulic stop can measure the log and therefore optimise woodscrap management.

DH-PRO-600-P: The wood is conveyed by a trough equipped with a push-pull rod, guaranteeing speed and efficiency. When the end of the log is almost reached, the push-pull rod automatically moves backwards, the trough descends and the next log is put into position immediately, while the previous log is still being sawn. Significant time savings are made with this method.

The push-pull rod automatically measures the length of the log, thus optimising woodscrap management.

This model is also fitted with a 165 cm diameter circular saw.

A perfect combination of performance and reliability:

Productivity: the DH-PRO-600 is designed to process large volumes of wood within a short time, perfectly meeting the requirements of industries and large-scale production operations.

Robustness: designed for intensive use, it easily withstands the most rigorous operating conditions.

Power: our hydraulic power packs developed in-house guarantee high production rates, accompanied by motors sourced from major manufacturers.

Advanced automation: thanks to smart systems, the machine reduces end-of-stroke losses and guarantees clean, precise cuts.

Remote management: anomalies are detected rapidly by an integrated system, making maintenance and rapid resolution of issues easier.

Safety: full automation of the DV-PRO-1200 ensures optimal protection for operators and accessories.

Personalisation: do you need to process longer logs, disentangle logs or add other outfeed conveyors? Each configuration can be fully modified to adapt to your specific requirements.

Technical data

Wood diameter

From 8 to 60 cm

Length of logs

From 18 to 100 cm

Cutting system

Chain or circular

Splitting

Horizontal 2 x 22T

Commands

Automatic

Drive

Electric

Kindling production

No

Wood loading system

15 mm steel feed belt or trough with push-pull rod for length adjustment

Wood holding system in the saw

Hydraulic clamps or roller

System for tilting wood towards the splitter

Lifting tray or turnstile

Wood holding system in the splitter

Hydraulic press

Cutters

2 independent cross-cut blades in wear-resistant steel

Type of chain

404 18H

Type of circular saw

Carbide blade

Splitter actuators

200 to 300 bars

Motor power

45 kW min.

Oil volume

900L min.

Electric

General PLC + safety relay or safety PLC

Oil flow rate

From 210 to 360

OPTION

Remote control

OPTION

Push-pull rod for length adjustment on the feed belt

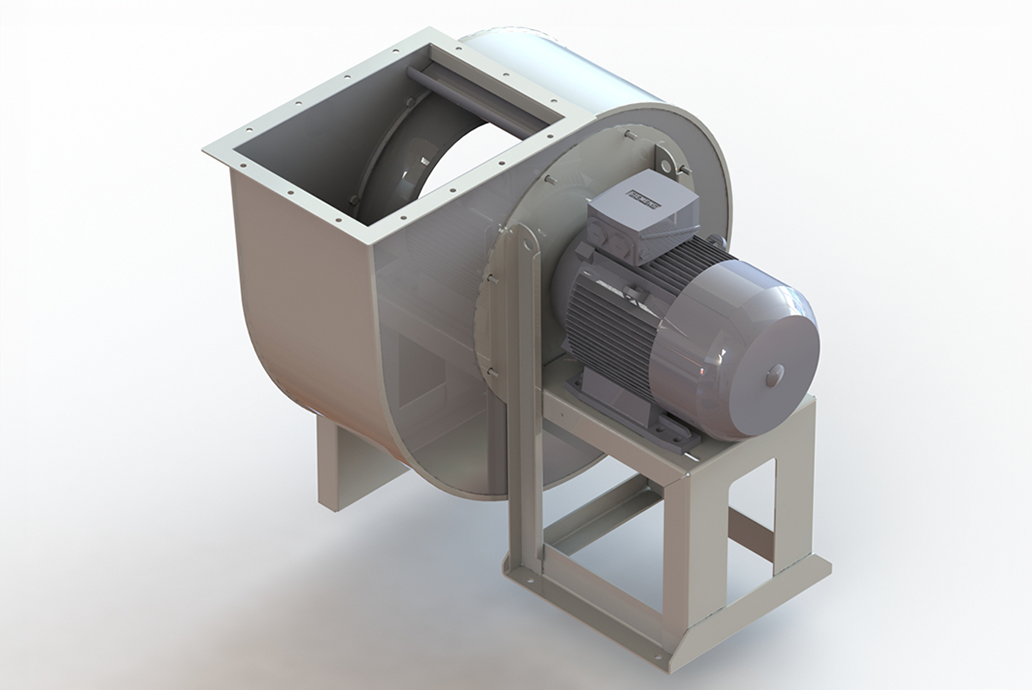

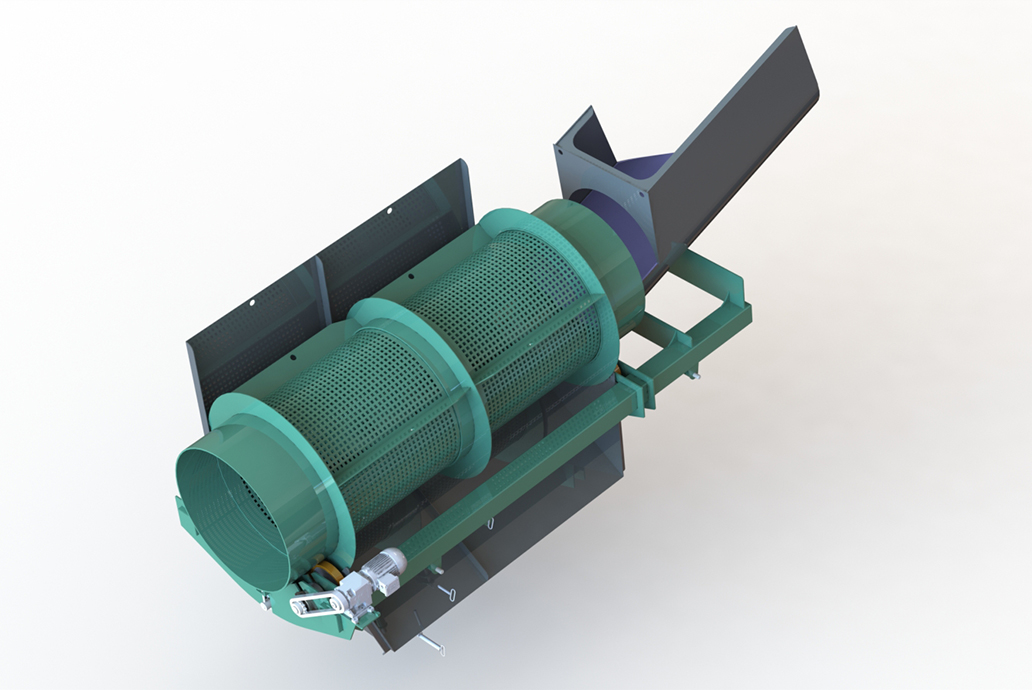

Photos

Photos